Cold chain stereo library

With the improvement of people's living standards, the demand for high-end food increases, coupled with the whole society began to pay attention to food safety, China's food cold chain logistics ushered in a rapid development. At the same time, the competition of traditional room temperature logistics is fierce, and the profit rate drops sharply, which makes the field of cold chain logistics increasingly become the focus of enterprises. As an important infrastructure of cold chain logistics, with the support of market incentives and policies, cold storage projects continue to emerge in all parts of China, but high standard cold storage resources are still scarce.

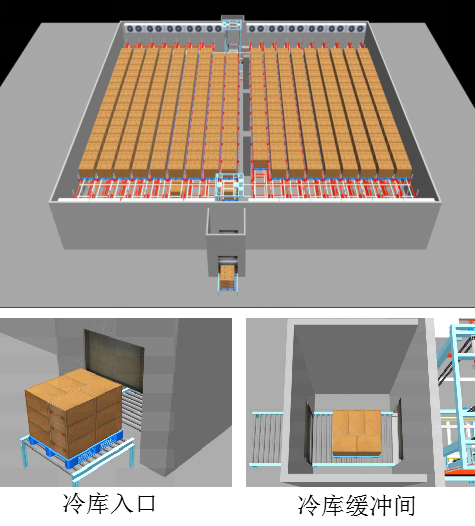

Automated solid cold storage with "high efficiency, energy saving, intelligence, environmental protection, fully meet the personalized needs of logistics enterprises" as the project design concept, using shuttle, elevator, WMS system, storage system, monitoring system and other fully automated logistics equipment, the use of RFID and bar code technology, greatly improve the operating efficiency. And can realize the goods "first in, first out" and selective shipment, to ensure the quality of storage goods.

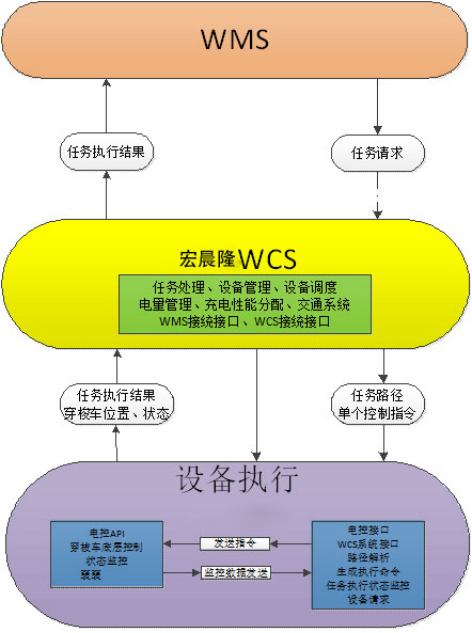

Automated solid cold storage adopts WCS, WMS, TMS, OMS and other information management systems, which can greatly improve the operation efficiency of cold storage, and the operation efficiency is 2~3 times that of traditional cold storage.

In the aspect of intelligent identification of goods, the use of handheld laser scanner (PDA), infrared sensors, GPS and other system equipment, to realize the real-time positioning, tracking, monitoring and management of goods in the cold storage. In addition, the Internet of Things technology is used to realize the real-time sharing and docking of information sent and received by upstream and downstream enterprises.

Automatic three-dimensional cold storage adopts professional cold chain logistics management technology, which can ensure the accuracy and operability of product information, realize the comprehensive information of cold chain items can be queried online, and provide customers with the whole traceability service of entrusted items in the supply chain.

The advantages of automatic solid cold storage in refrigeration system are as follows:

1) High degree of automation. The system is fully automatic operation, high degree of automation, normal operation does not need manual operation. When there is a need for manual operation, the system only needs to issue instructions to the system, and the system will automatically execute the instructions, eliminating the hidden danger caused by manual operation errors.

2) Establish customer and product information according to different customers, each customer has an independent file in the WMS system. System administrator according to the customer delivery note according to the product name, batch number, quantity, specifications and other information in the WMS system to establish a goods receipt, at this moment the single information automatically into PDA handheld computers, according to customer's delivery tally clerk mononuclear new documents in the PDA information, and according to the actual cargo scanning tray number, forklift will be scanned tray on conveyor automatic warehousing, After storage, the stacker will send the pallet to the storage location according to the system instruction. After warehousing is completed, the goods location information, pallet number information and goods information are correspondingly bound as the inventory information, and the system issues the operation bill.

3) Select storage according to product characteristics, and store different products in different partitions. The warehousing products can be stored in isolation. According to different product characteristics and customer needs, the WMS system divides the storage status of products into qualified products, uninspected products and unqualified products, etc. Inventory products can be queried online through product regulations, batches, suppliers and other relevant information, so as to achieve full monitoring of stored goods.

4) The system administrator establishes the goods delivery order according to the customer's order, and sets it in the system according to the customer's personalized needs. The system can carry out "first in, first out" or selective shipment of product batches.

5) After the selection of documents is completed, the system administrator will click the outbound warehouse. At this time, the stacker will automatically look for the warehouse location of outbound products according to the document information and exit the warehouse. The tallyman will arrange the shipping operation according to the display screen at the shipping port.

Scope of application: cold chain logistics, fresh electricity, third-party logistics, pharmaceutical and other industries warehouse safe and stable storage and distribution of goods, the lowest temperature can reach -25℃.

Warehouse Management Software

低温密集库适用于冷链物流、生鲜电商、第三方物流、医药等行业仓库安全、稳定进行货物存储和配送,最 低温度可达-25℃。