Adopt passive electronic tag, long life, maintenance free, unique design, and can be well embedded in the plastic pallet, not easy to be collision and wear in the process of pallet transportation. In addition, the electronic tag can be repeatedly written data, is conducive to solve the pallet goods adjustment, assembly and other warehousing logistics problems, the label can be recycled, greatly saving the cost of users. The system realizes long-distance identification, fast and reliable reading and writing, can adapt to the dynamic reading of conveyor belt operation, in line with the needs of modern logistics. In the tag information processing have adopted advanced data compression technology, make the electronic tag carries tray cargo information (packets), scan the tray electronic tags can be a more information items, exempt from down the tray and resources needed for the heavy tray, save time, reduce the error rate and the damage probability, achieve fast and accurate inventory count, Improve the overall transparency of enterprise logistics. Improve the reliability of data in the management information system, efficient and accurate data collection, improve operation efficiency, partition inventory, real-time and timely work guide, accurate and efficient use of scarce resources, improve production and operation capacity

RFID warehouse management

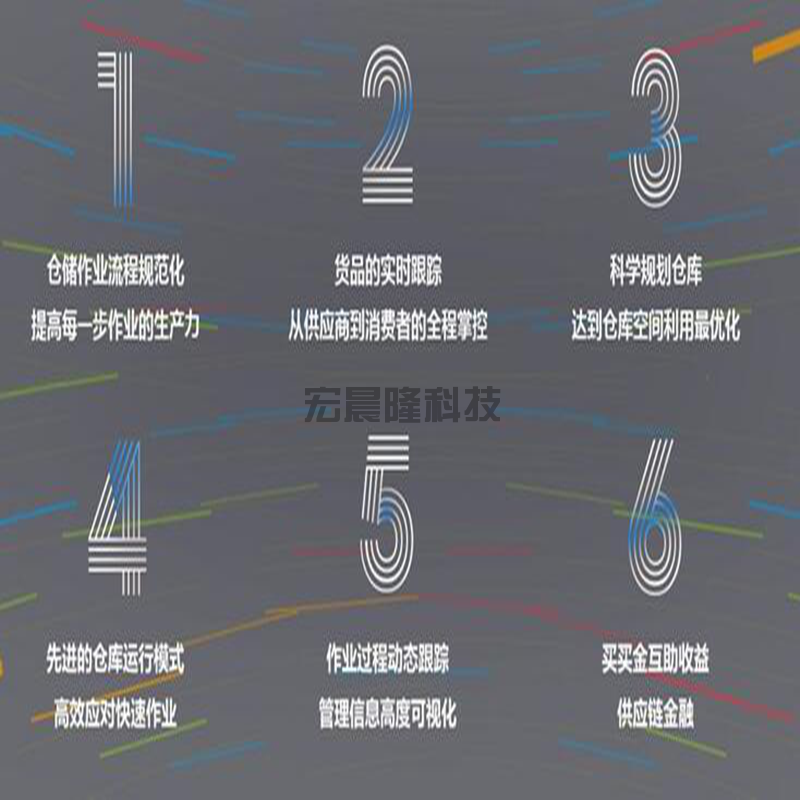

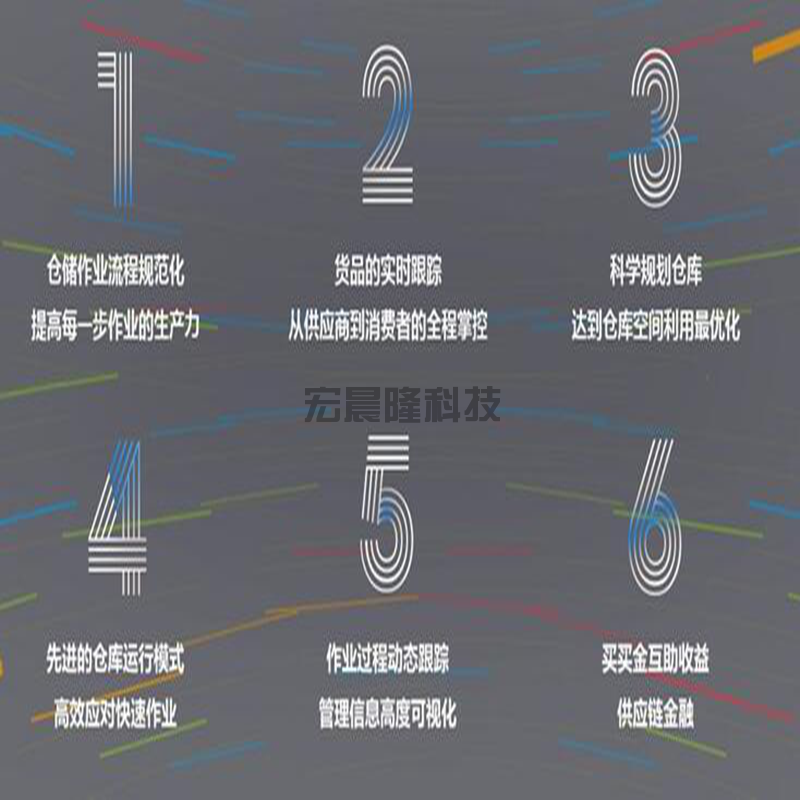

RFID, commonly known as "electronic tag", is a non-contact automatic identification technology, it automatically identifies the target object through the radio frequency signal and obtain relevant data, identification work without manual intervention, as a wireless version of bar code, RFID technology has the advantages that bar code does not have, such as waterproof, antimagnetic, high temperature resistance, long service life, large reading distance, data on the label can be encrypted, larger data storage capacity, storage information change freely and so on. RFID brings revolutionary changes to warehouse management:

Automatic in and out of the library: the stable reading and writing distance of the hand-held reader can reach 2-5 meters, the reading and writing distance of the fixed reader can reach more than 12 meters, and the effective identification distance can reach more than 30 meters if the active electronic tag is used. It effectively solves the problem that barcode storage must be scanned manually in the past, realizes automatic warehousing and greatly improves the labor cost of warehousing and the use efficiency of forklift.

Dozens of tags can be read instantly: Once the tag enters the magnetic field, the reader can read the information immediately. Using RFID anti-collision technology and fixed reader, dozens of tags can be read instantly, greatly improving scanning efficiency and reducing labor costs.

Screen free reading: Labels cannot be obscured when scanning a traditional bar code. RFID is able to communicate through non-metallic and opaque materials such as paper, wood and plastic without the need for a light source. Provide better scanning experience, can quickly tally, find goods, inventory. It's the warehouse management accelerator.

Reuse: RFID tag content can be changed, the direct benefit is that the RFID tag can be reused, get rid of the traditional bar code tag can only be used once, can effectively reduce the cost of enterprise consumables (enterprises using bar code storage system every year to purchase a large number of labels and carbon tape)

Security: RFID electronic tags can not only be embedded or attached to different shapes and types of products, but also set password protection for reading and writing of label data, so as to have higher security; : As RFID carries electronic information, its data content can be protected by password, making its content difficult to be forged and fabricated, with higher security.

Miniaturization and diversification of shapes: RFID does not need to match the fixed size and printing quality of paper for reading accuracy. It is more suitable for miniaturization and diversification of forms, so as to facilitate embedding or adhesion on products of different shapes and types.

Large data capacity: A dimensional barcode has a capacity of 50Bytes, a two-dimensional barcode has a maximum capacity of 2 to 3000 characters, and an RFID has a maximum capacity of MegaBytes. With the development of memory carrier, the data capacity is also expanding. In the future, items will need to carry more and more data, and the demand for the expanded capacity of the label will increase accordingly.

Long service life, adapt to harsh environment: RFID radio communication mode, so that it can be applied to dust, oil and other highly polluted environment and radioactive environment, with a life of more than 10 years (100,000 times read and write); The carrier label paper of traditional bar codes is vulnerable to contamination, but RFID is highly resistant to substances such as water, oil and chemicals. In addition, because the bar code is attached to plastic bags or outer packing cartons, so particularly vulnerable to damage; RFID label is the data stored in the chip, so it can be free from contamination, RFID anti-pollution ability and durability.