Manufacturing alone, smart factories and the Industrial Internet of Things (IoT) are expected to generate $196 billion in cumulative GDP growth over the next 15 years, driven by China's current policies and investment trends. Even more value will be created if the impact of the Internet of Things is further expanded.

The McKinsey Global Institute predicts that the economic impact of smart factories will be worth between $1.2 trillion and $3.7 trillion annually by 2025. Accenture and Frontier Economics estimated the cumulative GDP impact of smart factories and industrial IoT on 12 industries in China. Driven by China's current policies and investment trends, manufacturing, smart factories and the Industrial IoT alone could generate $196 billion in cumulative GDP growth over the next 15 years; Even more value will be created if the impact of the Internet of Things is further expanded. Taking manufacturing as an example, the economic value created by the Internet of Things will jump from $196 billion to $736 billion, an increase of 276%.

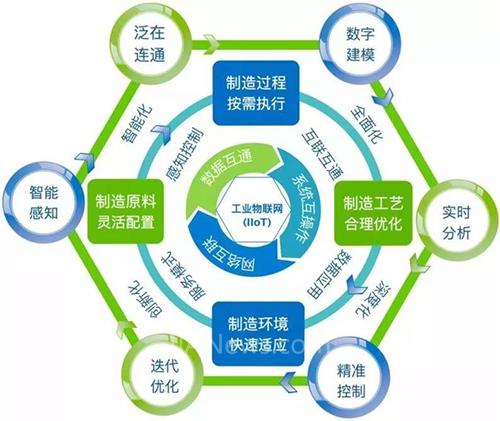

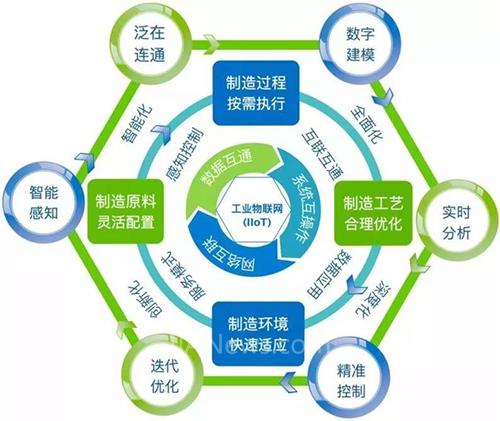

Figure 1 McKinsey 2025 Internet of Things Estimated Value Report (Unit: trillion USD)

Technological innovation and new challenges

Smart factory represents the digital age of high connectivity and intelligence. The intelligence of the factory is reflected in the five key areas of interconnection, digitalization, big data, intelligent equipment and intelligent supply chain. Typical smart factories include: production equipment interconnection, item identification and positioning, automatic detection of energy consumption, equipment status monitoring, remote product operation and maintenance, accessories product traceability, production performance assessment and factory environment monitoring, and other existing practical applications.

At present, compared with traditional industrial manufacturing, smart factory has several obvious technological innovations:

● Intelligent sensing control - through the use of intelligent sensing technology to collect industrial data anytime, anywhere

Comprehensive interconnection - delivers the collected data accurately and in real time through a variety of communication technology standards

● Deep data application - using cloud computing, big data and other related technologies, data modeling, analysis and optimization, to achieve the full mining and utilization of massive data

The original service mode - the use of information management, intelligent terminals and platforms and other technologies, to achieve the traditional industrial intelligent transformation, enhance the value of the industry, optimize the service resources and stimulate industrial innovation.

On the basis of these technological innovations, Smart Factory will face six technical development trends, that is, terminal intelligence, ubiquitous connectivity, marginalization of computing, network flattening, service platform and security improvement. The resulting management changes include the increasing diversification of equipment connection, the tilting of data processing to the edge, the transformation of enterprise strategy from industry individual to ecosystem, and the transfer of enterprise operation from equipment and assets to products and customers.

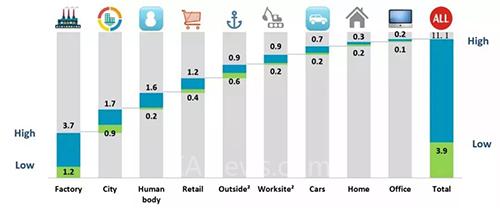

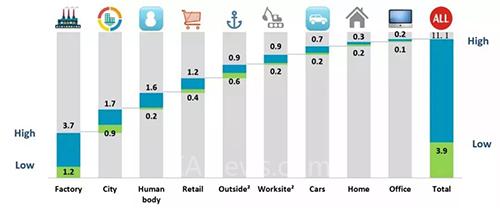

Figure 2 Schematic diagram of operation process of intelligent factory led by the Industrial Internet of Things

Changes in technology and trends have brought new challenges, such as the lack of unified technical standards, the need to strengthen industry standardization, the low level of industrial informatization among Chinese enterprises, the need to speed up application and promotion, the uneven development of enterprises, and the difficulty in replicating successful models.

Special data ownership issues hang in the balance, and data security issues need to be addressed. Therefore, from the national and enterprise levels, in the face of these challenges, the overall layout standardization task of the industrial Internet of Things needs to be implemented in stages, network connectivity and data heterogeneous integration and other basic technical issues need to be solved, including standardizing the packaging of resource data and building a good ecological environment for application and innovation. In addition, it is necessary to build a safe environment for the Industrial Internet of Things to prevent and control safety issues.

Problems to be solved and technical realization of smart factory

As an inevitable trend of industrial development in the future, intelligent factories need to solve many problems in the face of many technical challenges. By analyzing these problems that need to be solved, we can sort out which technologies and products are used for technical realization. In particular, as the first exhibition of electronic information technology in China, you can find various product technologies and system solutions to help realize the smart factory at the booth of various manufacturers when you visit the 2019 Shanghai Electronics Fair in Munich.

The first problem to be solved by the smart factory is the intelligent perceptual control, which can obtain the most critical industrial data through the collection of industrial data anytime and anywhere. In terms of technology realization, practical problems can be solved through various sensing control technologies, which involves many technologies including sensors, equipment identification, industrial control and so on.

At the Shanghai Electronics Fair in Munich, BOSCH (booth No. E4.4500), AMS AG AMEX (booth No. E4.4524), TE Connectivity (booth No. E6.6508), ALPS (booth No. E5.5600) and P+F + Fuchs (booth No. E1.1556), Banner Bonner (booth number: E1.1560) are the leading manufacturers of industrial sensors, with the help of a variety of high-precision and high-reliability sensor products, you can achieve accurate industrial data acquisition. In the field of industrial control systems and devices, ST STMicroelectronics (booth number E4.4108), Renesas and Cypress (E5.5100 Smart Factory Science Park), Adi Adeno Semiconductor (E5.5100 Smart Factory Science Park), Qualcomm Qualcomm (E5.5100 Smart Factory Science Park) and Broadcom (E5.5100 Smart Factory Science Park) are all employees Important supplier of industrial control components.

Figure 3: Exhibitors of Smart Factory Science Park

The second problem to be solved is the comprehensive interconnection. It is a very important technical challenge to transmit the collected data in real time and accurately, and ensure the safety and reliability of signal transmission as well as the compatibility with different devices. The technologies needed to deal with this problem include industrial Ethernet, short-range wireless communication and low-power industrial wide area network technologies and related solutions.

During the Shanghai Electronics Fair in Munich, you can get connectivity technology solutions at the booths of Honeywell (booth number E4.4559), Cypress (booth number E5.5100) and TDK (booth number E5.5106).

With data acquisition and data transmission, the intelligent core of a smart factory comes from the deep application of data. Cloud computing, big data and other related technologies are used to model, analyze and optimize data, so as to fully mine and utilize massive data. The data processing technologies involved in this area include data cleaning, data analysis, data modeling and data storage, in addition to the algorithms and equipment services we are familiar with, such as cloud computing.

Fig. 4 Various industrial IoT standardization organizations are complex

During the Shanghai Electronics Show in Munich, Cypress (E5.5100 Smart Factory Technology Park) will showcase a new generation of storage platforms with embedded computing capabilities to meet the growing demand of smart factories for highly reliable smart technologies and trouble-free storage products. The platform has a standardized IP design that can be quickly reconfigured for new application requirements. Cypress's Semper NOR line of flash memory is built on this platform, which uses an ARM Cortex M0 processor to provide reliable, durable data retention in the extreme operating temperatures of industrial applications.

Finally, the most special challenge for smart factories will be the innovation of service models, integrating information management, intelligent terminals and platforms and other technologies to achieve intelligent transformation of traditional industries. This aspect involves a lot of service mode innovation outside of the technology, and the most special point is the security management technology, especially encryption authentication, firewall and intrusion detection and other technical links, to ensure the comprehensive security of the smart factory. By connecting to the network, customers can monitor the running state of machinery from inside and outside the plant, exchange data, change production instructions, and rewrite the MCU storage program to update equipment Settings. This requires the system manufacturer to provide a more secure, more reliable, more friendly man-machine interface and reprogramable integrated solution.

Along with the wave of the fourth industrial revolution, the new generation of information technology will bring profound influence to the traditional manufacturing industry. From the "Industry 4.0" advocated by Germany to intelligent manufacturing and the Industrial Internet of Things, the transformation and upgrading of the manufacturing industry has become an irreversible trend. Rising labor costs and raw material prices are forcing factories to adopt more efficient automation solutions. On the other hand, facing the growing personalized demand of consumers, factories need to establish a mechanism to quickly respond to diversified demands. The establishment of a smart factory is a huge systematic project, and the vast number of developers will be important creators who participate in the development of some part of this huge system project.

Macro morning long technology co., LTD. Is located in the guangdong zhuhai grand bay area between the three major urban belt -- -- -- -- -- zhuhai golden bay port industrial zone, since its inception, the company focused on intelligent three-dimensional warehouse, intelligent AGV carrying, wisdom and factory automation stereoscopic warehouse, intelligent dense warehouse, four to shuttle car, stacker, three-dimensional library shelves, automatic packing machine, AGV handling car, cold chain cold storage, robot palletizer, palletizer, logistics conveying system, automatic loading and unloading car system, automatic sorting and picking system, logistics automation equipment, information integration, MES manufacturing execution system, WMS warehouse management system, intelligent storage system, intelligent factory, edible oil filling production line, Filling production line, intelligent warehouse, packaging equipment and other intelligent equipment research and development, design, manufacturing, installation and debugging, technical services and packaging line solutions integration services. Company is mainly for edible oil, beverage, water, feed, new energy, cosmetic, pharmaceutical and other industries provide automated secondary packaging equipment (out of the box machine, packing machine, sealing machine), palletizing equipment and system (stacker crane, tear open buttress machine), intelligent three-dimensional warehouse (stacker, RGV/AGV dolly, three-dimensional shelf), transmission system, intelligent truck and other high-end intelligent complete sets of equipment Integration with the whole line system.